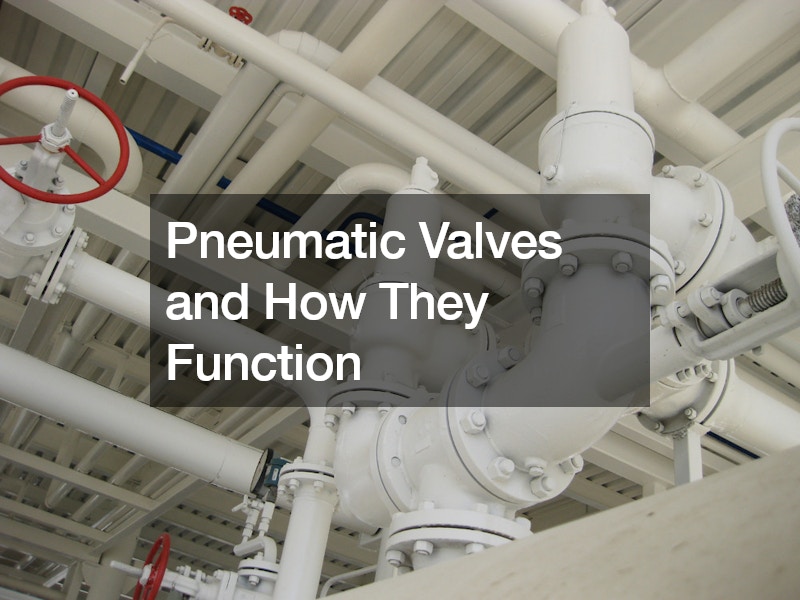

Pneumatic Valves and How They Function

Pneumatic valves are essential components in pneumatic systems, playing a crucial role in controlling the flow of compressed air. These valves utilize pneumatic energy to regulate the passage of air through the system, enabling various operations such as directing, stopping, or modulating airflow. The function of pneumatic valves is relatively straightforward yet crucial for pneumatic systems’ overall performance. They typically consist of a valve body, actuator, and internal components such as seals and springs.

When activated by an external signal, such as an electrical or manual input, the valve actuator initiates a mechanical motion that opens or closes the valve’s passage, allowing or obstructing the flow of compressed air.

Pneumatic valves come in various types, including directional control valves, proportional valves, and flow control valves, each designed for specific applications and operating conditions. For instance, directional control valves regulate the direction of airflow, while flow control valves adjust the airflow rate to control the speed of pneumatic actuators. These valves find extensive use in industries such as manufacturing, automotive, and aerospace, where pneumatic systems are prevalent. They are employed in a wide range of applications, including machine automation, assembly lines, pneumatic tools, and industrial machinery. Pneumatic valves are fundamental components of pneumatic systems, enabling precise control over airflow and facilitating various industrial processes. With their reliability, versatility, and efficiency, pneumatic valves play a vital role in ensuring the smooth operation of pneumatic systems across diverse industries.